Champion-PTAC Wall Sleeve – Problems Solved

- Champion-PTAC Condensate Drain Pan. Manufactured from high strength ABS the Champion-PTAC Condensate Pan is the first and only of its kind. Back by our lifetime guarantee our Champion Condensate Drain Pan will not rust out, corrode, or degrade for any reason. Combine that with its ability to withstand uncharacteristic amounts of condensation makes our product truly unique and will save contractors and hotel owners alike tremendous amounts of time and expensive repairs costs associated with mold, mildew and property water damage that are eminent failures modes of all other PTAC wall sleeve systems.

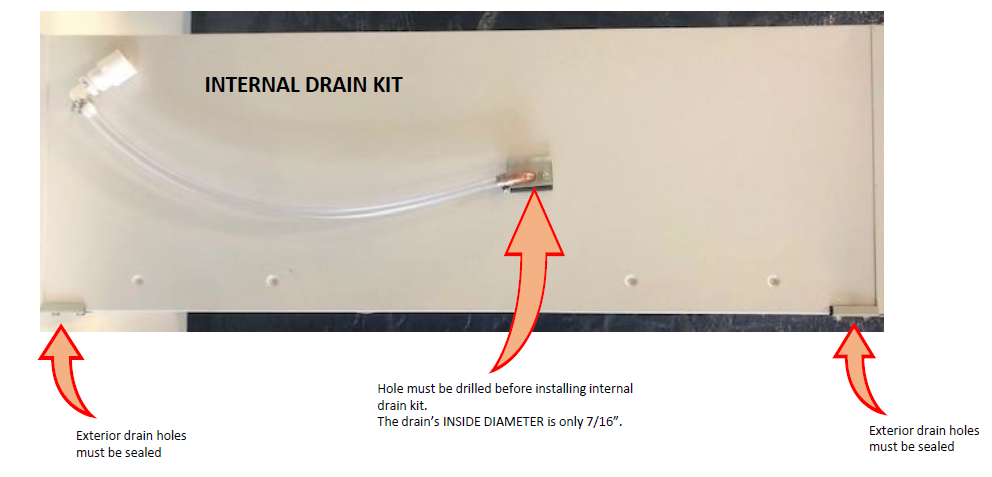

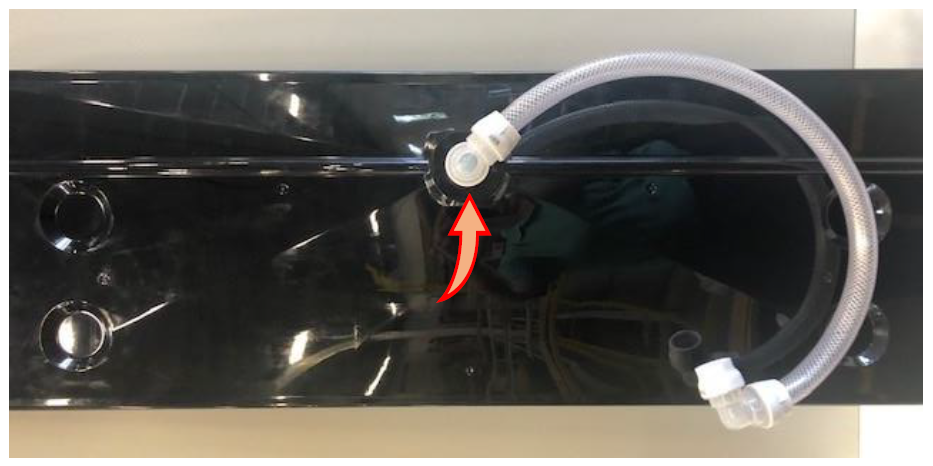

- Champion-PTAC ¾ “Quick Connect Drain Assembly. Our 3/4” Quick Connect Drain Assembly is simple and extremely easy to install. Unlike our competition that requires drilling, PVC glue and other specialty tools to install our flexible re-enforced PVC tubing with push on fittings makes any installing quick, easy, and guaranteed leak free.

- Unlike all our competition, Champion-PTAC Pellet Delivery System eliminates costly maintenance and room down-time by eliminating the need to remove the PTAC unit for condensate pan cleanings as our pellets are introduced to the unit through our proprietary and patented delivery system. Located on the bottom right corner of the sleeve, anti-coagulant pellets are introduced into the wall sleeve guaranteeing that system build up will not compromise the drainage system. In addition to the AC pellets, Champion Air Freshener Pellets can also be easily applied through this delivery system, eliminating any unpleasing smells that may arise from daily use.